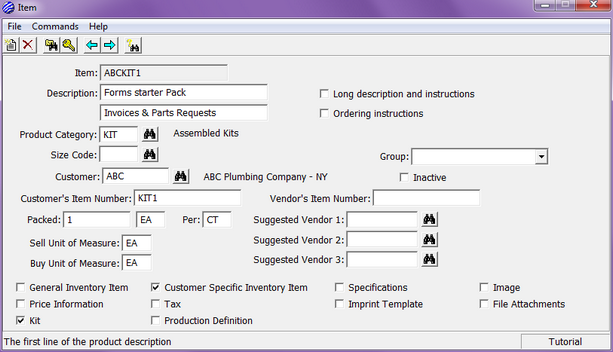

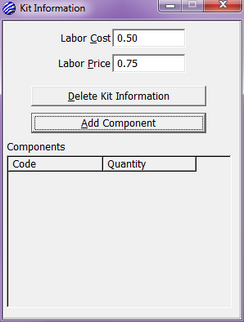

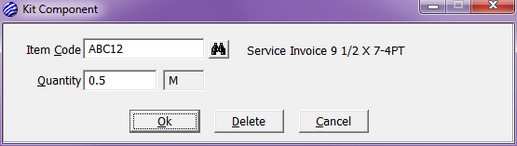

Preparing the Item Record — An Item record must be created for each different kit. The unit of measure for kits will normally be EA. The item should be flagged as a Customer Specific Inventory Item with a control unit of measure of EA. The Kit check box will display the Kit Information Window. Labor Cost and Price may be entered. The entries should reflect the cost and price of assembling one kit. An unlimited number of components may be added. Each component must have an item record and be set up as a Customer Specific Inventory Item. The Unit of Measure on the component will be the CS unit of measure specified for the item. The contents of the Kit must be expressed in that unit of measure. In this example, we are using two items that are controlled in M and are including 500 (.5 M) of each in the kit.

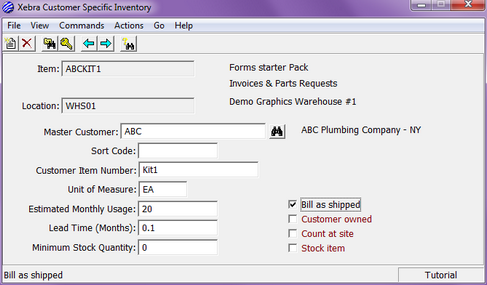

Preparing the CSI Control Record — A control record must be set up for each different kit. The location should be the warehouse where the kits will be stored or released from. Even if kits are produced only on demand, the Customer Specific Inventory program Must go through the storage and release process for the kits in order to capture the usage reporting information required.

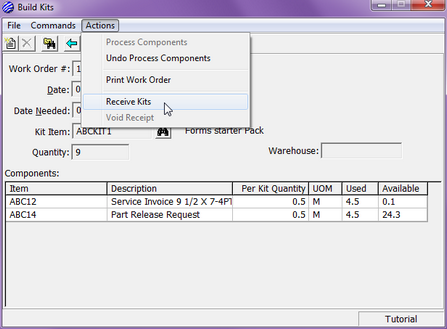

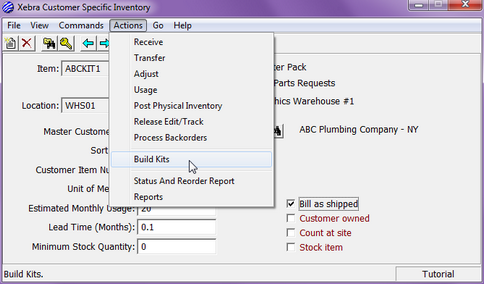

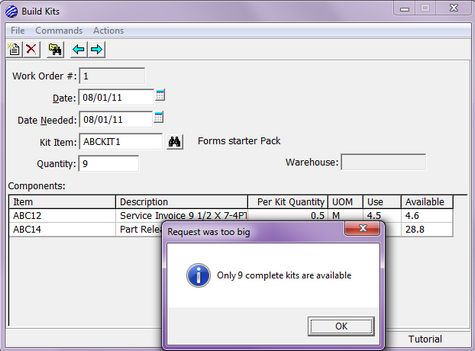

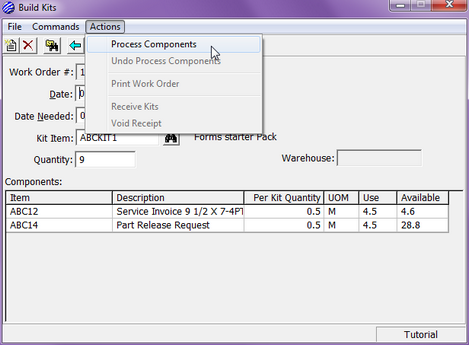

Building Kits — When a request for kits is received, the operator will use Actions>Build Kits to open the Build Kits Window. When the Kit Item and the quantity are identified, the list box of components will show the quantities needed and available for each component.

Should their be insufficient components to make the number of kits requested, the quantity requested will be changed to the maximum that can be made and the operator will be notified.

Processing the Kits

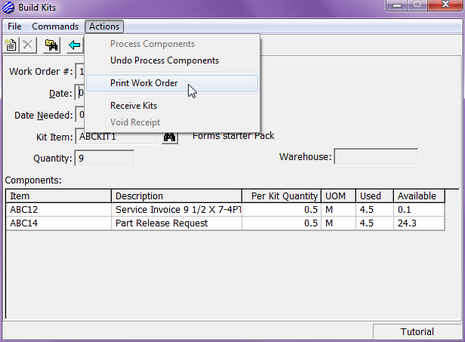

Process Components — Actions>Process Components. This action creates usage transactions that reduce the inventory of all of the components required to produce the kits.

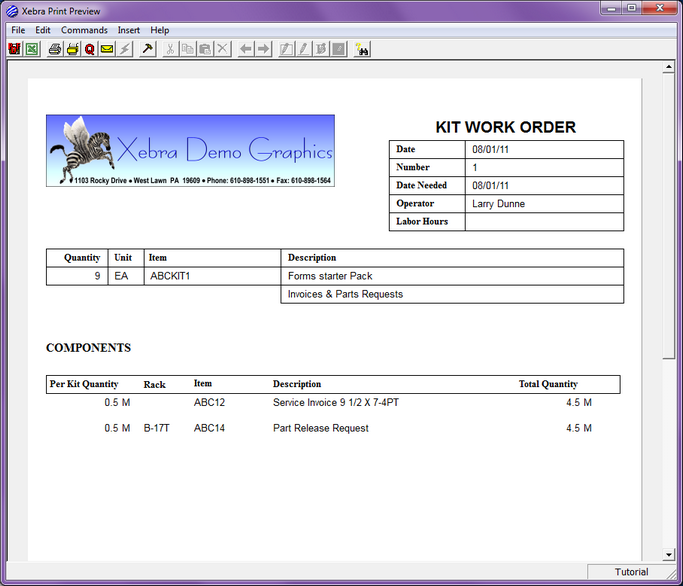

Print Work Order — Actions>Print Work Order. This action produces a document for use in preparing the kits.

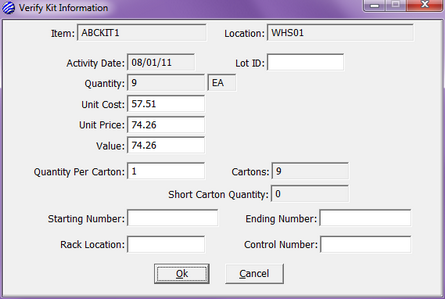

Receive Kits — Actions>Receive Kits. This action receives the finished kits into inventory so that they can be released to the customer. In situations where the kits are being produced on demand and not stored, it is easier to do this step before the kits are actually produced. The kits can then be released and the Packing List can be produced and sent to the warehouse with the work order. The Verify Kit Information is presented when the kit work order is selected from the list. The Unit Cost, Price, and value are the sum of the components plus the labor cost or price as appropriate. Generally, these should not be changed. If the customer is to be billed at a different rate than the price, the change should be made on the billing job when it is created. If components are pulled from lots with different cost, price, and/or value figures, the kits are priced using the average cost, price and/or value of each component. Xebra uses very strict lot control pricing to maintain accurate inventory value and usage figures.